Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

Table of ContentsThe Main Principles Of Motorcycle Parts New Zealand Specialists 8 Simple Techniques For Motorcycle Parts New Zealand SpecialistsThe Of Motorcycle Parts New Zealand SpecialistsThings about Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand SpecialistsNot known Incorrect Statements About Motorcycle Parts New Zealand Specialists The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking AboutWhat Does Motorcycle Parts New Zealand Specialists Mean?

So, connect to one of our experts today.CNC machining modern technology is swiftly ending up being the centerpiece of lots of different manufacturing processes around the globe as a straight result of its several benefits over various other techniques. Additionally, the sectors that produce bikes have jumped on board with this pattern. The most cutting-edge business are currently developing their engine parts and wheels using machining techniques initially established for motorcycle components.

On the other hand, the effects of industry are the primary focus of this short article. Allow's obtain right right into it. You may be wondering why we make use of. It is not difficult to fathom the factors that resulted in this outcome. Since we have your interest allow us explain the reasoning behind this modern development in the motorbike production industry.

More About Motorcycle Parts New Zealand Specialists

Furthermore, you have total control over the appearance of the components, even down to the minute details. Occasionally, motorcyclists might decide to fix up their experience by mounting aftermarket parts or customizing the bike's remodeling. As soon as again, computer system mathematical control (CNC) machining is one of the most practical method. Upgrades may be of any form and design you desire.

Fascination About Motorcycle Parts New Zealand Specialists

CNC machining may be utilized to make virtually all of a motorcycle's steel and plastic parts. To continue, we'll go over a number of machined components for motorbikes.

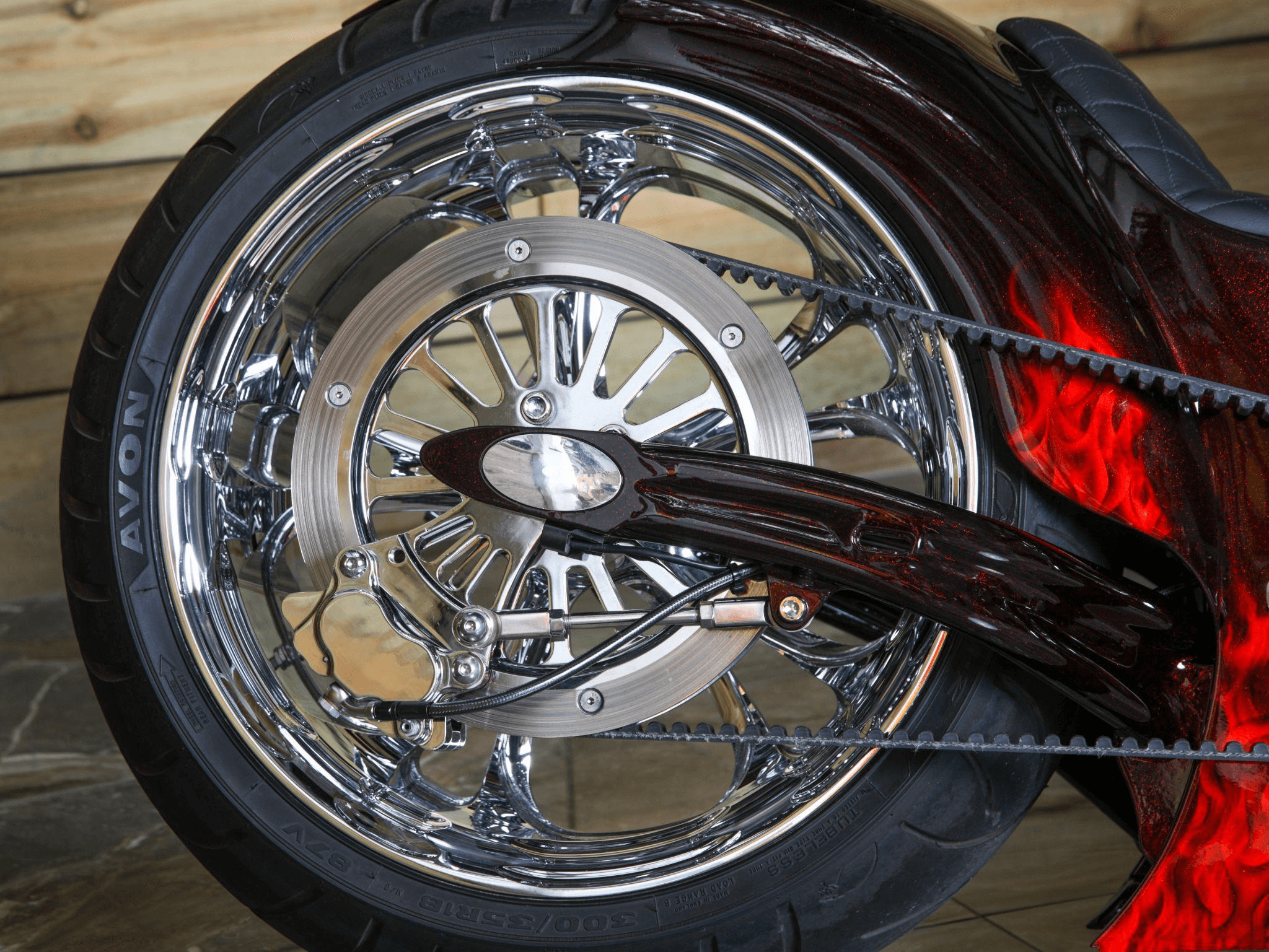

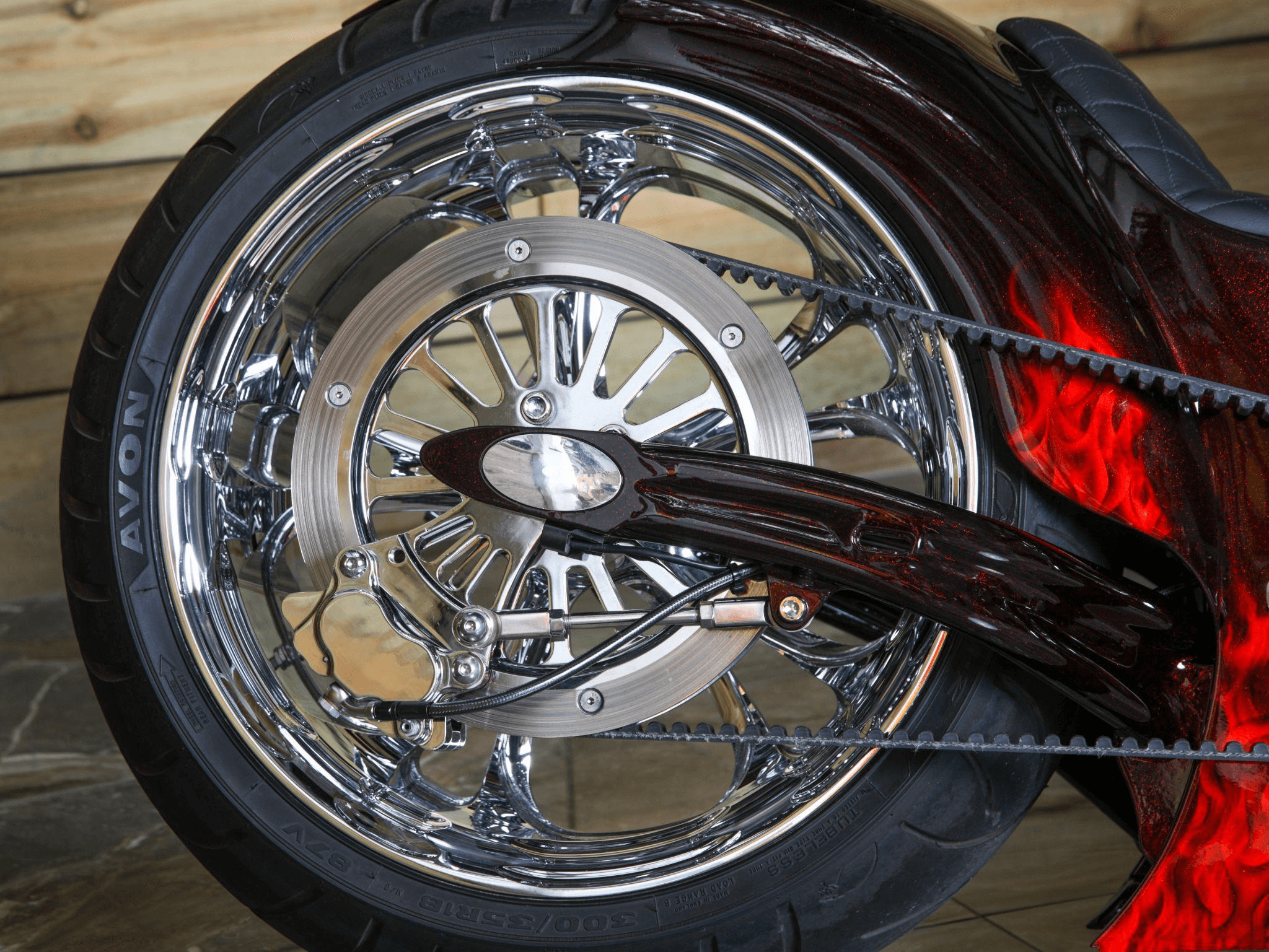

When tailoring the wheels, the disks are where the emphasis must be. The bulk of them are made out of aluminum. Light weight aluminum alloys are popular for the impressive machining capabilities that they possess. Milling treatments are utilized to obtain the desired degree of wheel personalization. Another aspect of the bike that may be customized is the tires.

7 Simple Techniques For Motorcycle Parts New Zealand Specialists

When it concerns a car (or a motorbike), the most essential part is the engine. Several people mention it as the "heart" of the car. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be intricate and need layouts with a high degree of accuracy.

Lights is one more complicated element of customization. Usage only top quality things, nonetheless, because these lights are crucial for the safety and security of motorcyclists and other drivers or individuals when traveling, specifically in the evening. Motorbike fronts lights have 3 main parts: the light bulb, or source of light, the lens, and the housing. Particularly, we customize the lens and the housing.

Milling processes with a remarkable coating would result in the lenses having a reflective top quality that is comparable to that of a Continued mirror. The cover, on the various other hand, is not made up of fragile materials; rather, it is built out of hard polymers that can be machined right into even more detailed patterns.

Motorcycle Parts New Zealand Specialists for Beginners

They typically have sophisticated geometries with a riches of minute information. Motorbike makers typically cast these elements, however only for the manufacturing of bespoke components. CNC machining is the technique of choice when producing distinct pieces. Machining on 5 axes in today's globe is the ways by which any kind of style shape might be recognized.

The success of the procedure is contingent on the mill cutters' capacity to calculate refined and challenging angles properly. Select Runsom for your personalized motorbike parts! We have the capacity to fabricate complicated and elegant components making your bike unparalleled. Most are crafted from light weight aluminum or steel alloys, each of which has its uses and benefits.

Right here are a few instances of steels typically made use of in motorcycle component machining. Aluminum is the key material made use of by companies specializing in creating personalized motorcycle components to develop most of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to an additional metal that is very light in weight and has fantastic machining qualities as a result of its high mechanical strength. This material might be formed into practically any form and keeps its measurements well. Also mission-critical elements that need a high degree of accuracy might gain from their use.

The Buzz on Motorcycle Parts New Zealand Specialists

Another steel that sees heavy usage in special info the production of CNC-customized components is magnesium. It is amongst the lightest metals that are now easily accessible and has exceptional machinability attributes and stamina proportionate with its low weight. Among the downsides of magnesium is that its dust may easily ignite.

Due to its remarkable machinability and weldability, stainless steel is an alloy that is especially appropriate for CNC procedures. They have excellent rust resistance and a high aesthetic allure. Their most typical use in creating numerous motorbike components is fasteners, such as screws and screws. Their reduced susceptibility to oxidation and deterioration makes them optimal for this use.

The 15-Second Trick For Motorcycle Parts New Zealand Specialists

It seems that CNC turning and milling are the foundational procedures. Alternate techniques exist, such as exploration. Allow's investigate several of these machining strategies extensive. The CNC turning method is considered a subtractive manufacturing method. On top of that, it needs maintaining bars of product, usually plastic or steel, ready and after that twisting a cutting tool to remove sections of the product as the material is transformed.

These methods are equally vital and produce elements with high accuracy and regular quality. The processes aid enhance the general top quality of the machined bike components.

About Motorcycle Parts New Zealand Specialists